Welding, Fabrication and Assembly

Welding and assembly are the finishing processes of many metal products. Welding involves the joining of pieces of metal by utilising high current to generate heat to melt the metals being attached. Assembly is the attachment of components and sub-assemblies to form the completed part.

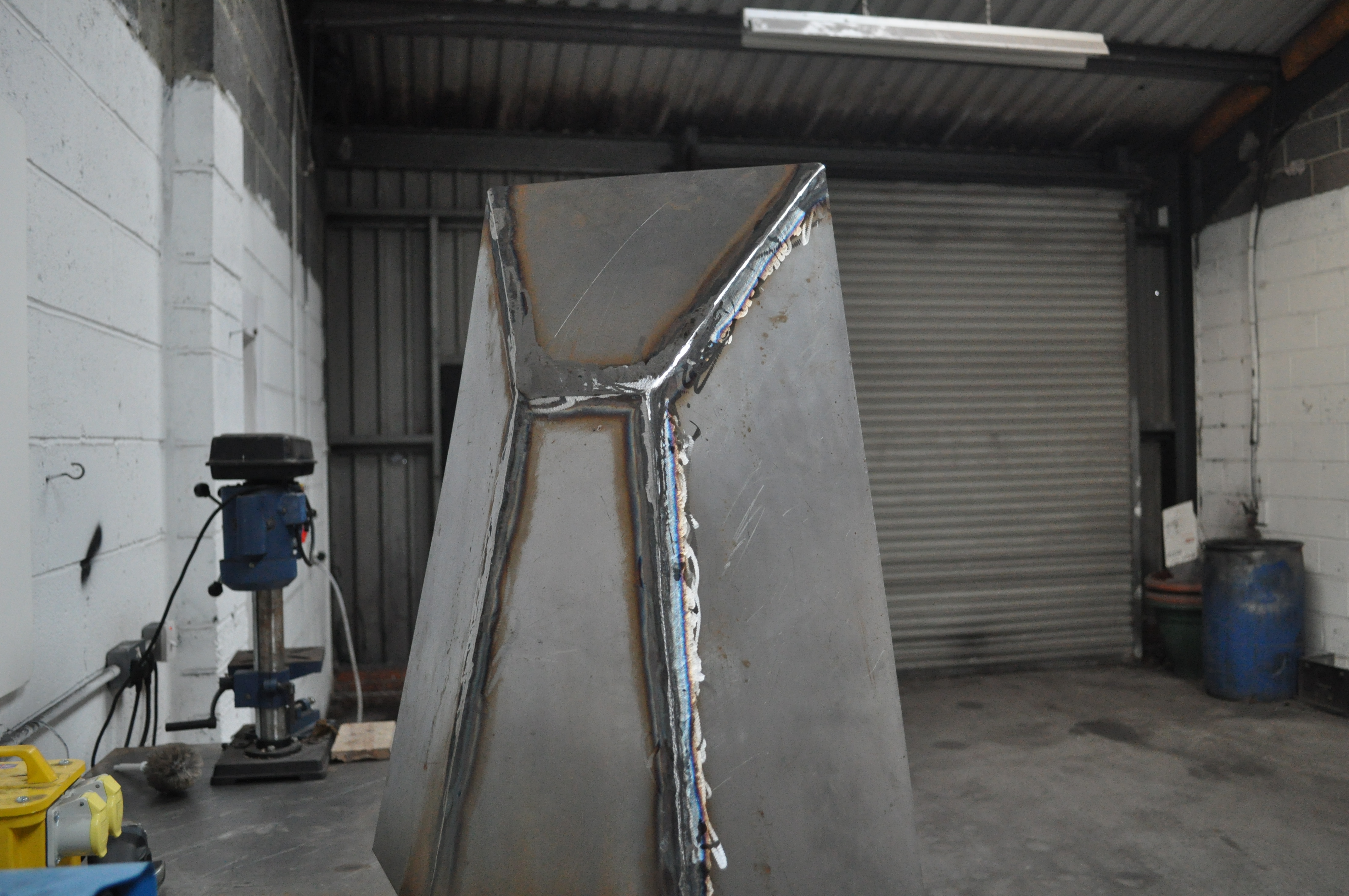

MIG (Metal Inert Gas) welding is our chosen welding process as it is effective and versatile. The MIG welding machine is also light weight and portable allowing for on site fabrication. For this reason flux cored weld wire is used which generates its own shield gas removing the need for separate shield gasses.

We assemble using a variety of mechanical fastenings such as rivets, pins and bolts. I can calculate loading in bolted and riveted connections if the application requires. I have performed many structural calculations involving a variety of mechanical fixings and fixing arrangements.

I have experimented with industrial adhesives and 3M tapes to great effect. Often these relatively new adhesives can offer large improvements over mechanical fastening. I have had many a 3M taped connection outperform a similar mechanical fastening arrangement, with the tape also being quicker to install and powder coatable.