Machine Inspection and Calibration

Precision CNC tooling only remains precise when correctly calibrated. Over long periods of use, wear can make tooling loose accuracy and precision.

I have identified machine inaccuracies through inspection and utilising custom machine programmes. Using mathematical modelling of wear rates I have derived machine calibration procedure and also defined inspection and calibration periods.

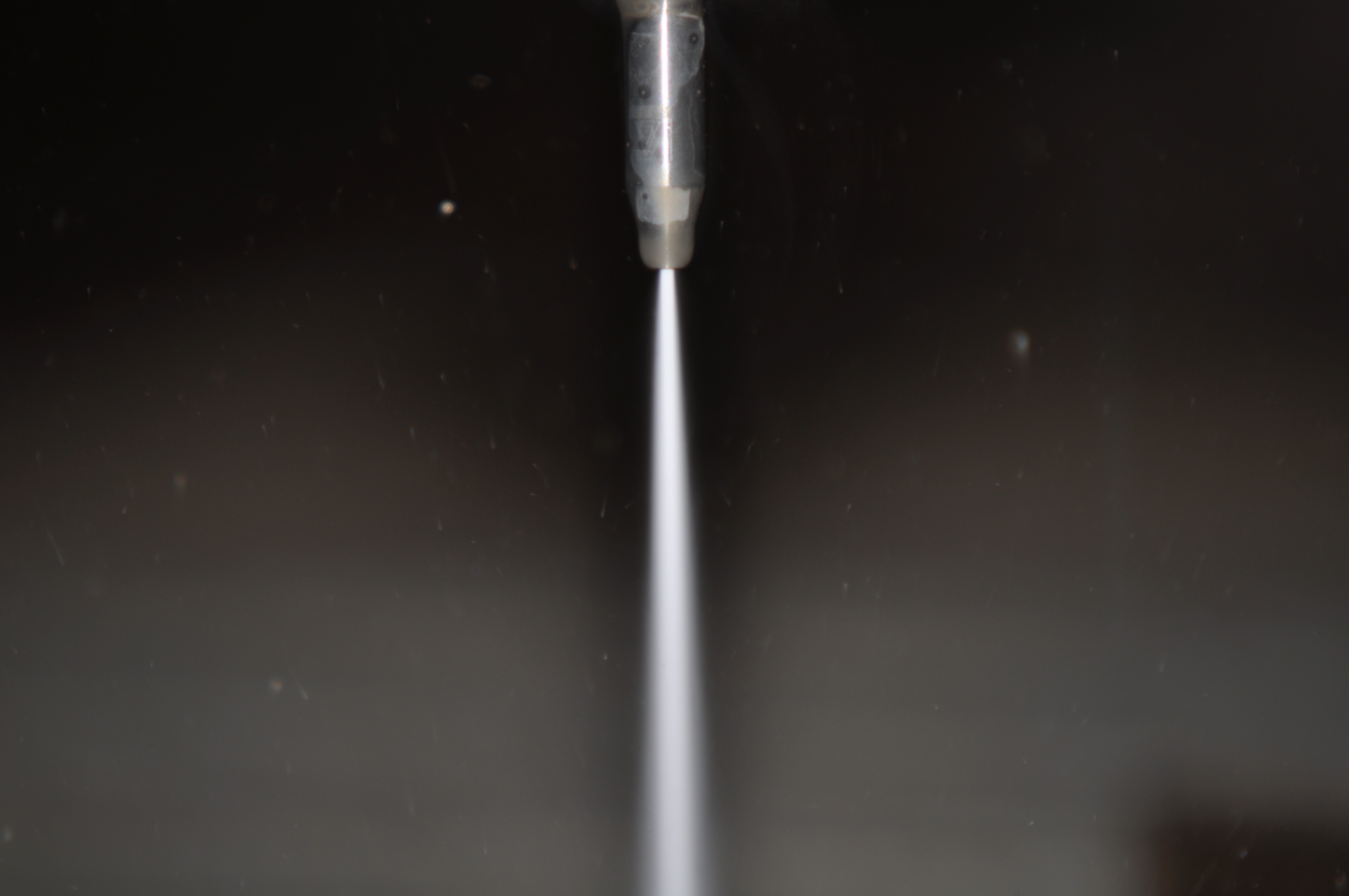

The images below were using in deriving the water jet beam divergence as a function of time on, jet pressure and cutting abrasive which was used to define the water jet offset in order to maintain accuracy.